Work in progress

Goals

- Offer interesting logistical experiments to students, here: plan, release and execute the order processing.

Background and strategic fit

See Why flecsimo?

Assumptions

- Orders will be provided from external systems or the order data is provided by the simulation manager (e. g. lecturer or lab-engineer)

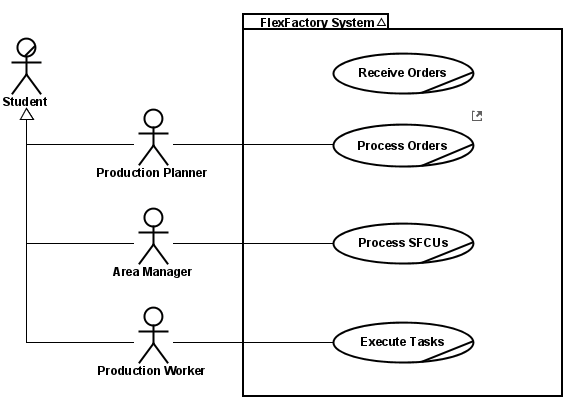

Requirements (Use Cases)

| # | Title | Use Case | Importance | Notes |

|---|---|---|---|---|

| OP-1 | Receive Orders | Optional | ||

| OP-2 | Process Orders | A Production Planner accepts or creates a new production order checks its feasibility and plans the location and schedule to process it. | Must have | |

| OP-3 | Process SFCUs | An Area Manager controls the processing of assigned Shop floor Control Units (SFCU's) | Must have | |

| OP-4 | Execute Production Tasks | One or more Production Worker execute or support assigned Production Tasks within a manufacturing cell | Must have |

User interaction and design

| UC: OP-2 Process orders | ||

| A Production Planner accepts or creates a new production order checks its feasibility and plans the location and schedule to process it. | ||

| Pre | A new Production Order has been received. | |

| Post | The Production Order has been released, and the corresponding information on the to-process Shop floor Control Units (SFCUs) has been distributed to the planned production areas (shops). | |

| Step | Actor intention | System responsibility |

|---|---|---|

| 1 | The Production Planner selects the "Process Order" view and selects the "check" function. | The System shows a list of all new / unchecked Production Orders. |

| 2 | The Production Planner selects one or more Production Order for "Check". | The Systems checks if the data is feasible to process, i.e. if the required Production Data Specification is known to the system. |

| 3 | The Production Planner starts planing of the location (area /shop) and the time schedule for the execution of the Production Order in the system. | The system computes and offers the feasible planning alternatives. |

| 4 | The Production Planner selects a Planning alternative and releases one or more Production Orders. | The System changes the Production Order status to "Released" and generates the corresponding Shop floor Control Data (including the required Production Data Specification) and transfers the data to the selected location |

| Alternatives and notes | ||

| 4A | [Data not feasible] tbd | |

| 5A | [No feasible planning alternative found] tbd | |

| 7A | [Planning alternatives not acceptable] tbd | |

| ||

User Interaction | ||

The wire frame shows the above use case in step 7. The user interaction could be like:

You may step through the use case by stepping through the pages of following wire frame specification: | ||

Questions

Below is a list of questions to be addressed as a result of this requirements document:

| Question | Outcome |

|---|---|

| No question yet |

Not Doing

- For first release no order editing or re-start will be possible

- No "Housekeeping" is planned for the first release, i. e. orders may not deleted via the GUI.