Work in progress

Goals

- Offer interesting logistical experiments to students, here: plan, release and execute the order processing.

Background and strategic fit

See Why FlexFactory?

Assumptions

- Orders will be provided from external systems or the order data is provided by the simulation manager (e. g. lecturer or lab-engineer)

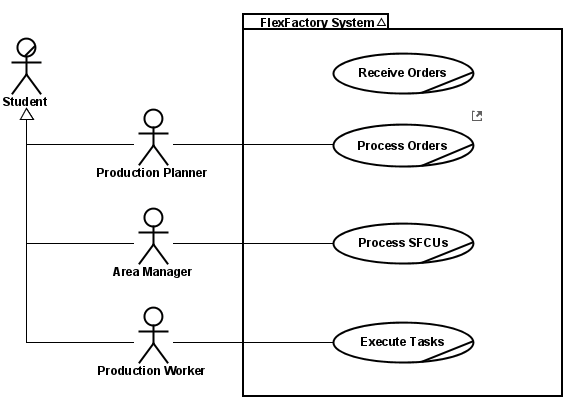

Requirements (Use Cases)

| # | Title | Use Case | Importance | Notes |

|---|---|---|---|---|

| OP-1 | Receive Orders | Optional | ||

| OP-2 | Process Orders | A Production Planner accepts or creates a new production order checks its feasibility and plans the location and schedule to process it. | Must have | |

| OP-3 | Process SFCUs | An Area Manager controls the processing of assigned Shopfloor Control Units (SFCU's) | Must have | |

| OP-4 | Execute Production Tsaks | One or more Production Worker execute or support assigned Production Tasks within a manufacturing cell | Must have |

User interaction and design

Use Case OP-2: Process Orders

| UseCase | OP-2 [business] Process Orders |

| Summary | A Production Planner accepts or creates a new production order checks its feasibility and plans the location and schedule to process it. |

| Actor | Production Planner |

| Precondition | A new Production Order has been received. |

| Postcondition | The Production Order has been released, and the corresponding information on the to-process Shopfloor Control Units (SFCUs) has been distributed to the planned production areas (shops). |

| Base Sequence | 1. The Production Planner selects the "Process Order" view and selects the "check" function. |

| Branch Sequence | 4A [Data not feasible] TBD |

| Exception Sequence | 8A [Processing fault] TBD |

| Sub UseCase | |

| Note | Invariant: both, success as problems have to be logged, any state change of the process has to be logged. |

The wire frame shows the above use case in step 7. The user interaction could be like:

- Select the "Process Order" View

- Select the "Release" Menu entry on the side bar

- Select one or more Production Orders.

Questions

Below is a list of questions to be addressed as a result of this requirements document:

| Question | Outcome |

|---|---|